LVL Plywood

2024/10/09LVL Plywood

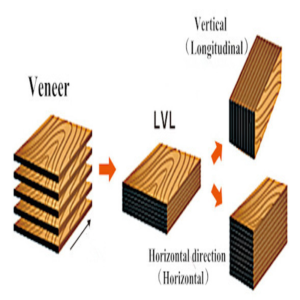

LVL Plywood (Laminated Veneer Lumber Plywood) is also known by names such as: unidirectional plywood, LVL plywood.

Manufactured from many layers of veneer laminated in one direction (parallel), bonded together with Melamine glue or Phenolic glue.

.jpg)

Characteristic:

- The layers of boards are stacked on top of each other and pressed together with glue and pressure.

- Better resistance to shrinking and warping than regular plywood.

- Able to withstand high loads.

- Widely used in construction industry.

- Use furniture to make wooden frames, columns and horizontal bars.

LVL plywood structure

Main specifications:

- Wooden core: Includes thin veneer panels from woods such as acacia, eucalyptus, fat, etc.

- Surface: no face

- Glue: 100% E0, E1, E2 glue or WBp waterproof glue, moisture-resistant and termite-resistant glue.

- Size: 1220-2440mm; as required

- Thickness: 9-75mm

- Tolerance +/-0.5mm

- Moisture content < 15%

Application:

- Used in many fields such as furniture (tables, chairs, cabinets, etc.), shutters and container floors.

- Use in applications requiring durability and dimensional stability.

- Used in both load-bearing walls, as frame and beam systems of housing structures, in building construction, high-rise projects.